|

| November 10, 2015 | Volume 11 Issue 42 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

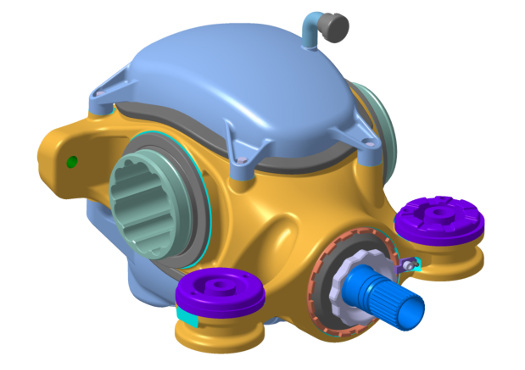

Ricardo shows off revolutionary ultra-lightweight rear drive unit

As a part of its contribution to the Ultra-Lightweight Transmission and driveline research project (ULTRAN), Ricardo engineers have designed an innovative rear drive unit for passenger vehicles based on a range of state-of-the-art technologies that delivers a product 25 percent lighter than current production. The unit was displayed publicly for the first time at LCV 2015, the Low Carbon Vehicle Event held in the U.K (Millbrook) Sept. 9-10.

The multinational ULTRAN research project aims to accelerate cost-effective lightweight drivetrain technologies in order to reduce the powertrain weight of future vehicles, and hence improve vehicle performance and reduce carbon dioxide emissions. The project is led by Jaguar Land Rover in a consortium including Ricardo, Tata Steel, Lubrizol, GRM Consulting Ltd, American Axle & Manufacturing, and the Universities of Southampton, Newcastle, and Warwick -- and is supported by InnovateUK. The project has developed, and is in the process of evaluating and demonstrating, a wide range of lightweight driveline technologies using the latest-generation Range Rover as the baseline for the research.

A major part of the Ricardo contribution to ULTRAN has been in the design of a rear drive unit. The unit is a clean-sheet design, based around a lightweight differential mounted within a compact, single-piece skeletal casing with tough, lightweight plastic covers.

"This unit can be adapted for almost any front, rear, or all-wheel driveline configuration, providing a highly cost-effective means of achieving a significant mass reduction -- proving that even highly scrutinized components can be improved significantly," said Jon Wheals, senior technologist of Ricardo Innovations.

In addition to being 25 percent lighter than current production, the unit is considerably more compact, so it frees up valuable package space. It is also stiffer, which provides improved noise, vibration, and harshness (NVH) performance. While innovative in design, the low-mass rear drive unit utilizes existing materials and manufacturing processes, so it could be applied in series production within three years following successful trials. Next-generation materials and manufacturing processes are being developed to further improve performance and weight reduction. By bringing together all aspects of design, manufacturing, and materials, ULTRAN aims to deliver a complete solution.

Beyond designing the ultra-lightweight rear drive unit, Ricardo has also manufactured prototypes of the unit for both rig- and vehicle-based testing and evaluation to confirm durability and the anticipated carbon dioxide impact. Ricardo activities on the ULTRAN project have also included further lightweight design and analysis studies on transmission, driveline, and dual mass flywheel systems.

"Complementary to the novel aspects comprising the new axle, this mass-reduction project is a great example of how Ricardo's approach to lightweight design, analysis, and optimization can deliver radical mass savings -- and consequent reductions in vehicle-based carbon dioxide emissions -- for all types of driveline and transmission systems," said Wheals.

Source: Ricardo

Published November 2015

Rate this article

View our terms of use and privacy policy